| Items |

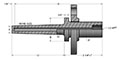

/Asset/a1624.jpg /Asset/a1624.jpg HF410V00908T2C8S 0.260 Inch (in) Bore Diameter and 1 Inch (in) Nominal Pipe Size "P" Heavy-Duty Van Stone Thermowell |

/Asset/a1624.jpg /Asset/a1624.jpg HF410V00908T2C22S 0.260 Inch (in) Bore Diameter and 1 Inch (in) Nominal Pipe Size "P" Heavy-Duty Van Stone Thermowell |

/Asset/a1624.jpg /Asset/a1624.jpg HF410V10908T2C8S 0.260 Inch (in) Bore Diameter and 1 Inch (in) Nominal Pipe Size "P" Heavy-Duty Van Stone Thermowell |

/Asset/a1624.jpg /Asset/a1624.jpg HF410V10908T2C22S 0.260 Inch (in) Bore Diameter and 1 Inch (in) Nominal Pipe Size "P" Heavy-Duty Van Stone Thermowell |

/Asset/a1624.jpg /Asset/a1624.jpg HF410V30908T2C8S 0.260 Inch (in) Bore Diameter and 1 Inch (in) Nominal Pipe Size "P" Heavy-Duty Van Stone Thermowell |

|||||

| Description | N/A Heavy-Duty Van Stone Thermowells are available in a variety of materials, flange sizes, and pressure ratings. They are also available in various lengths and with optional lagging extensions. Thermowell specifications should be determined based on process conditions which include strength, temperature, pressure and corrosion-resistance requirements. Heavy-duty Van Stone thermowells are supplied with a 0.260" or 0.385" bore diameter to accommodate sensing elements with 0.252" or 0.377" maximum diameter, respectively. Van Stone thermowells are connected using a separate and reusable lapped backing flange, eliminating the need for expensive flange materials. The tapered design is suited for heavy-duty applications where greater rigidity is required for increased pressure and flow due to process conditions. These wells are available as separate components or as part of complete sensor assemblies. | |||||||||

| Brands | N/A Pyromation® | |||||||||

| Nominal Pipe Size "P" | N/A 1 in | |||||||||

| Diameter of Pipe Size "P" | N/A 1.315 in | |||||||||

| Diameter "R" | N/A 2 in | |||||||||

| Diameter "Q" | N/A 7/8 in | |||||||||

| Diameter "V" at 0.260 Inch (in) | N/A 5/8 in | |||||||||

| Diameter "V" at 0.385 Inch (in) | N/A 49/64 in | |||||||||

| Well Type | N/A Heavy-Duty Van Stone | |||||||||

| Bore Diameter | N/A 0.260 in | |||||||||

| Flange Size | N/A 1 in | |||||||||

| Nominal Diameter (DN) | N/A 25 in | |||||||||

| Flange Type | N/A Van Stone (Lap Joint) | |||||||||

| Pressure Rating | N/A No backing flange | N/A No backing flange | N/A 150 Class | N/A 150 Class | N/A 300 Class | |||||

| Options |

N/A

316 Stainless steel well cap and chain Well stamped with customer-specified part number |

N/A

Brass well cap and chain Well stamped with customer-specified part number |

N/A

316 Stainless steel well cap and chain Well stamped with customer-specified part number |

N/A

Brass well cap and chain Well stamped with customer-specified part number |

N/A

316 Stainless steel well cap and chain Well stamped with customer-specified part number |

|||||

| Optional "T" Lag Dimension | N/A Specify "T" dimension in inches using two digits plus any fractional length | |||||||||

| Note for Material | N/A Specify two digit material code as stated in the Thermowell Material Table located earlier in section | |||||||||

| Additional Information |

N/A

Maximum tapered length is 16" ("U" length for non-lagging wells) = "S" - 2" ("U" length for lagging wells) = "S" - 2" -"T" (To solve for "T"), "T" = "S" -"U" - 2" (When "U" and "S" are specified) |

|||||||||

|

|

||||||||||